MFT Gateway is a hosted Software as a Service (SaaS) solution that enables file exchange over the AS2 or SFTP protocol, without the need to install or maintain.

- Blog

- Just-in-Time Manufacturing Meets Real-Time Data: EDI’s Role in Inventory Precision

EDI

Just-in-Time Manufacturing Meets Real-Time Data: EDI’s Role in Inventory Precision

Discover how EDI enhances Just-in-Time manufacturing with real-time data exchange, enabling inventory precision, speed, and supply chain harmony.

Kumudika Rupasinghe

Published: 29 Jul 2025

In the fast-evolving world of manufacturing, efficiency is a vital requirement. As industries streamline operations and reduce waste, Just-in-Time (JIT) manufacturing has emerged as a transformative approach to managing inventory. But as lean principles push boundaries, Electronic Data Interchange (EDI) has stepped up to supercharge JIT strategies. When just-in-time manufacturing EDI meets real-time data exchange, the result isn’t just speed. It’s precision.

Understanding Just-in-Time Manufacturing

At its core, JIT manufacturing is all about producing exactly what is needed, when it is needed, and in the quantity required. JIT slashes excess inventory and minimises holding costs. Instead of stockpiling raw materials and components, manufacturers rely on timely deliveries and flawless supply chain coordination.

However, this razor-thin margin of error means one late shipment or data mishap can halt production. That’s where technology comes in. EDI acts as the glue that binds manufacturers, suppliers, and distributors in seamless synchronisation.

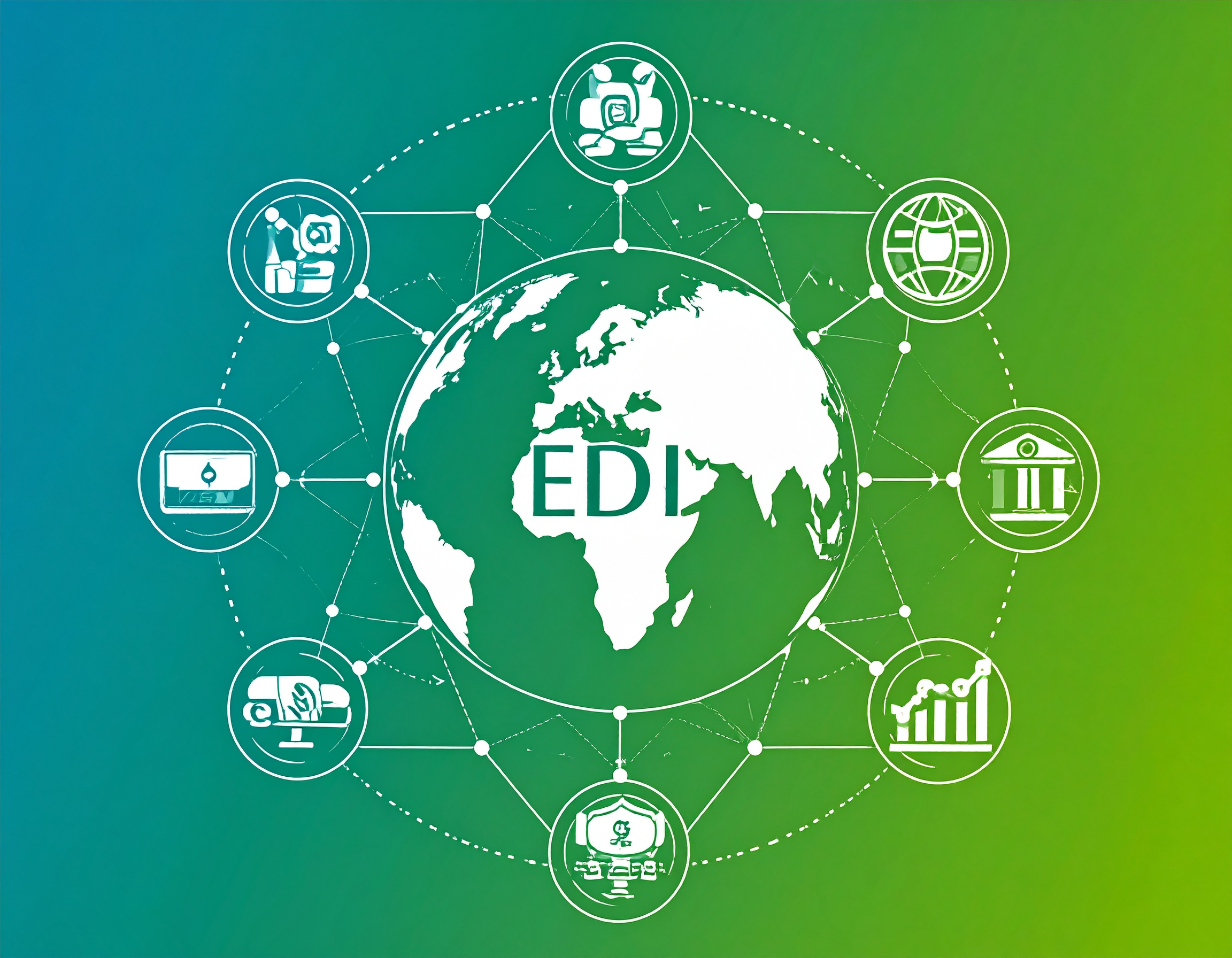

What Is EDI and Why Does It Matter?

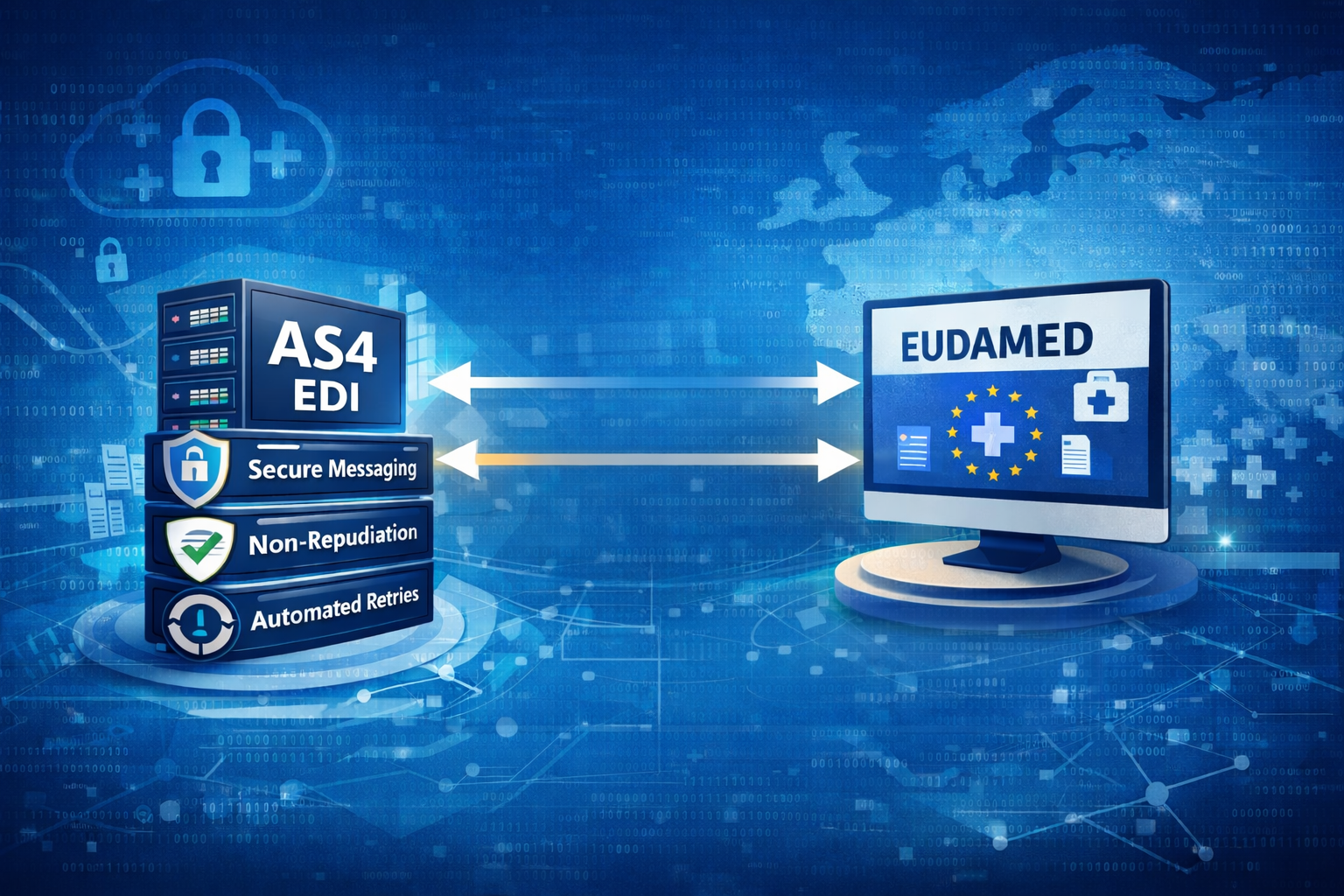

Electronic Data Interchange (EDI) is the automated exchange of business documents between organisations in a standardised format. It replaces traditional paper and email communications, slashing manual effort and errors. EDI handles purchase orders, invoices, shipping notices, and inventory levels instantly and securely.

When integrated into manufacturing workflows, EDI inventory management delivers the kind of responsiveness that JIT manufacturing demands. Businesses gain real-time visibility into stock levels, vendor shipments, and demand fluctuations — all without human intervention.

The Power of Real-Time Inventory Precision

Inventory precision isn’t just a buzzword. It’s the lifeblood of a successful JIT system. Imagine a supplier shipping the exact quantity of microchips needed for tomorrow’s assembly line. With EDI integration, the manufacturer receives advanced ship notices and real-time inventory updates, allowing precise forecasting and production planning.

Key Benefits of EDI in JIT Inventory Management:

- Improved Order Accuracy: EDI eliminates manual data entry, reducing order errors and ensuring parts arrive on time.

- Faster Processing Speeds: Documents that once took hours or days to send now reach partners in seconds.

- Reduced Inventory Costs: Real-time data means companies can keep leaner stock levels without risking shortages.

- Enhanced Supplier Collaboration: EDI enables tight-knit partnerships through shared visibility and trust.

EDI’s Role in a Digital-First Manufacturing Ecosystem

The convergence of just-in-time manufacturing EDI and digital transformation is reshaping factory floors. IoT sensors, AI-powered analytics, and cloud computing all thrive when fed with accurate, timely data. EDI functions as the real-time nervous system connecting these elements.

Manufacturers now rely on EDI not just for transactions, but as part of their strategic intelligence. By integrating EDI with MES (Manufacturing Execution Systems) and SCM (Supply Chain Management), businesses unlock proactive insights into bottlenecks, supplier performance, and production trends.

While inventory is the most immediate beneficiary, EDI’s ripple effects extend further:

- Customer Satisfaction: Faster fulfilment and fewer errors translate to happier customers.

- Regulatory Compliance: Automated records simplify audits and ensure data consistency.

- Scalability: EDI systems grow effortlessly with expanding supplier networks and global markets.

Smart EDI and Predictive Inventory

As artificial intelligence joins the mix, EDI is getting smarter. Predictive inventory management powered by machine learning can anticipate demand spikes, forecast shortages, and suggest optimal reorder points, leveraging EDI-fed data streams.

For manufacturers, this means less guesswork and more precision. Soon, we will be able to see factories where sensors detect dwindling stock, trigger an EDI-based reorder with the supplier, confirm shipment details, and update production schedules.

Conclusion

Just-in-time manufacturing thrives on timing and trust. And in today’s digital landscape, trust is built through data. By embracing EDI inventory management and investing in manufacturing EDI integration, businesses can harmonise supply chains, accelerate production, and reduce risk.

Whether you’re a small manufacturer or a multinational giant, integrating EDI into your JIT strategy is a smart and essential choice.

Need a cloud-based EDI solution with secure AS2? EDI Generator lets you receive, view, and send EDI documents perfect for automating manufacturing workflows. Request a Free Demo to learn more.

Talk to an EDI Expert

Join hundreds of organizations already taking full control of their B2B AS2 communications with our trusted solutions. Contact us today to tailor a solution that fits your specific AS2 EDI needs.

Related Articles

View All BlogsExplore our product stack

Try before you buy with a 30-day Free Trial

No commitment, all value. Try the AS2 Solution Risk-Free and discover how our solutions can transform your business workflows. No credit card required.

Explore Your Possibilities

Elevate AS2 Communications with our EDI and AS2 Solutions

See how our AS2 and EDI solutions can simplify your integrations, boost efficiency, and keep you compliant—request a personalized demo today.