MFT Gateway is a hosted Software as a Service (SaaS) solution that enables file exchange over the AS2 or SFTP protocol, without the need to install or maintain.

- Blog

- Best Practices for Walmart EDI Success

EDI

Best Practices for Walmart EDI Success

Discover key Walmart EDI best practices to avoid penalties and keep your supply chain running smoothly by reading our blog.

Rusiri Samarakoon

Published: 29 May 2025

Doing business with Walmart comes with great opportunity and equally high expectations. As one of the largest retailers in the world, Walmart relies heavily on Electronic Data Interchange (EDI) to manage its supply chain with precision. For suppliers, mastering Walmart’s EDI requirements is not just about compliance—it’s about keeping goods moving, invoices processing, and partnerships strong.

Here are three essential best practices to help ensure ongoing success with Walmart’s EDI system:

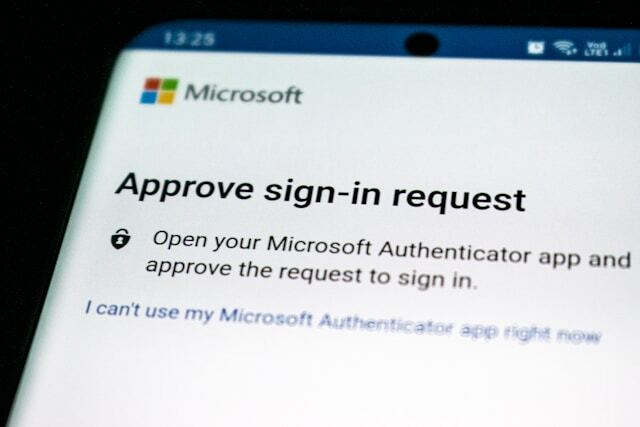

1. Daily Monitoring of EDI Transactions

Walmart expects suppliers to operate with near real-time responsiveness. This means EDI documents such as Purchase Orders (850), Advance Ship Notices (856), and Invoices (810) must flow without interruption or delay.

Why it matters: Even a single missed or late EDI document can result in shipment delays, chargebacks, or disrupted replenishment cycles.

Best Practice Tip: Set up automated alerts and reports to monitor the status of inbound and outbound EDI documents. Ensure someone on your team checks these daily to catch and address any failed transmissions or validation errors quickly.

2. Proactive Error Resolution

Errors happen—but how quickly and thoroughly you resolve them makes all the difference. Functional Acknowledgments (997s), ASN rejections, and mismatched invoice data are among the most common issues suppliers face.

Why it matters: Unresolved errors can snowball into downstream problems—unpaid invoices, incorrect shipments, or vendor performance penalties.

Best Practice Tip: Build a workflow to identify, log, and resolve errors as soon as they occur. Use your EDI dashboard, Walmart’s Retail Link, and supplier support resources to get to the root cause. Train your team to handle common errors proactively, and document recurring issues to help prevent them long-term.

3. Keep Up with Changes in Walmart’s Requirements

Walmart regularly updates its supplier and EDI requirements. Whether it’s a formatting change in the 856 ASN or an update to labeling standards, staying informed is essential to avoid non-compliance.

Why it matters: Suppliers who miss updates may find themselves out of spec—resulting in rejected shipments or delays in payments.

Best Practice Tip: Regularly check the Retail Link portal and Walmart Supplier Center for announcements and documentation updates. Consider assigning someone on your team to track compliance changes and coordinate updates with your IT or EDI provider.

Conclusion

Walmart’s supply chain success depends on efficient, accurate EDI—and by extension, so does yours. With daily monitoring, proactive problem-solving, and a commitment to staying up-to-date, you can turn EDI from a compliance obligation into a competitive advantage.

Need help navigating Walmart EDI requirements? Whether you’re just starting out or scaling up, aligning your EDI strategy with best practices can help you avoid penalties and improve your supplier scorecard.

To make this even easier, try our EDI Generator designed to simplify EDI document creation and ensure compliance with Walmart’s standards, saving you time and reducing errors.

Talk to an EDI Expert

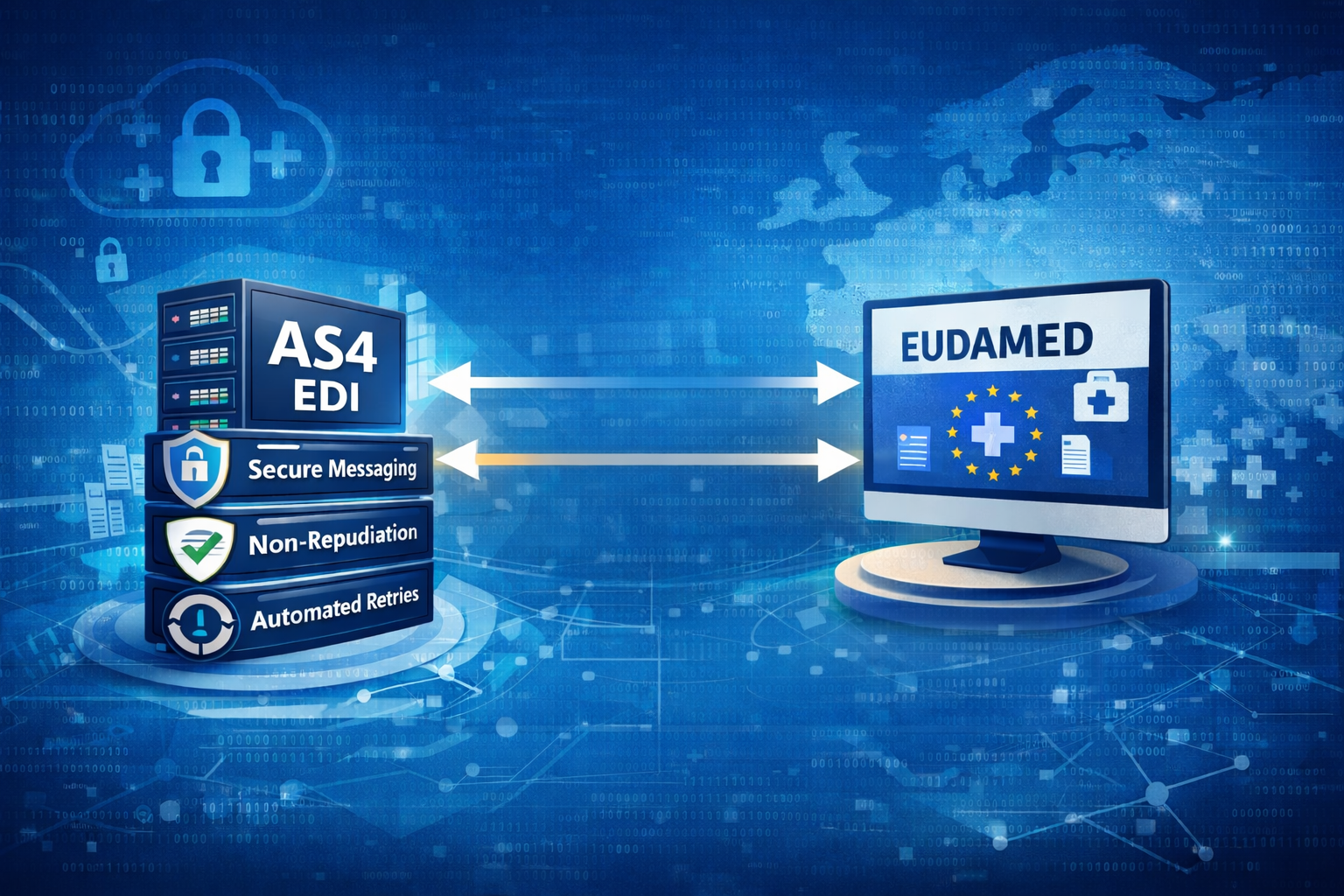

Join hundreds of organizations already taking full control of their B2B AS2 communications with our trusted solutions. Contact us today to tailor a solution that fits your specific AS2 EDI needs.

Related Articles

View All BlogsExplore our product stack

Try before you buy with a 30-day Free Trial

No commitment, all value. Try the AS2 Solution Risk-Free and discover how our solutions can transform your business workflows. No credit card required.

Explore Your Possibilities

Elevate AS2 Communications with our EDI and AS2 Solutions

See how our AS2 and EDI solutions can simplify your integrations, boost efficiency, and keep you compliant—request a personalized demo today.